How to decorate the interior - a review of wall wallpapers. Do you dream of…

How to dry construction timber?

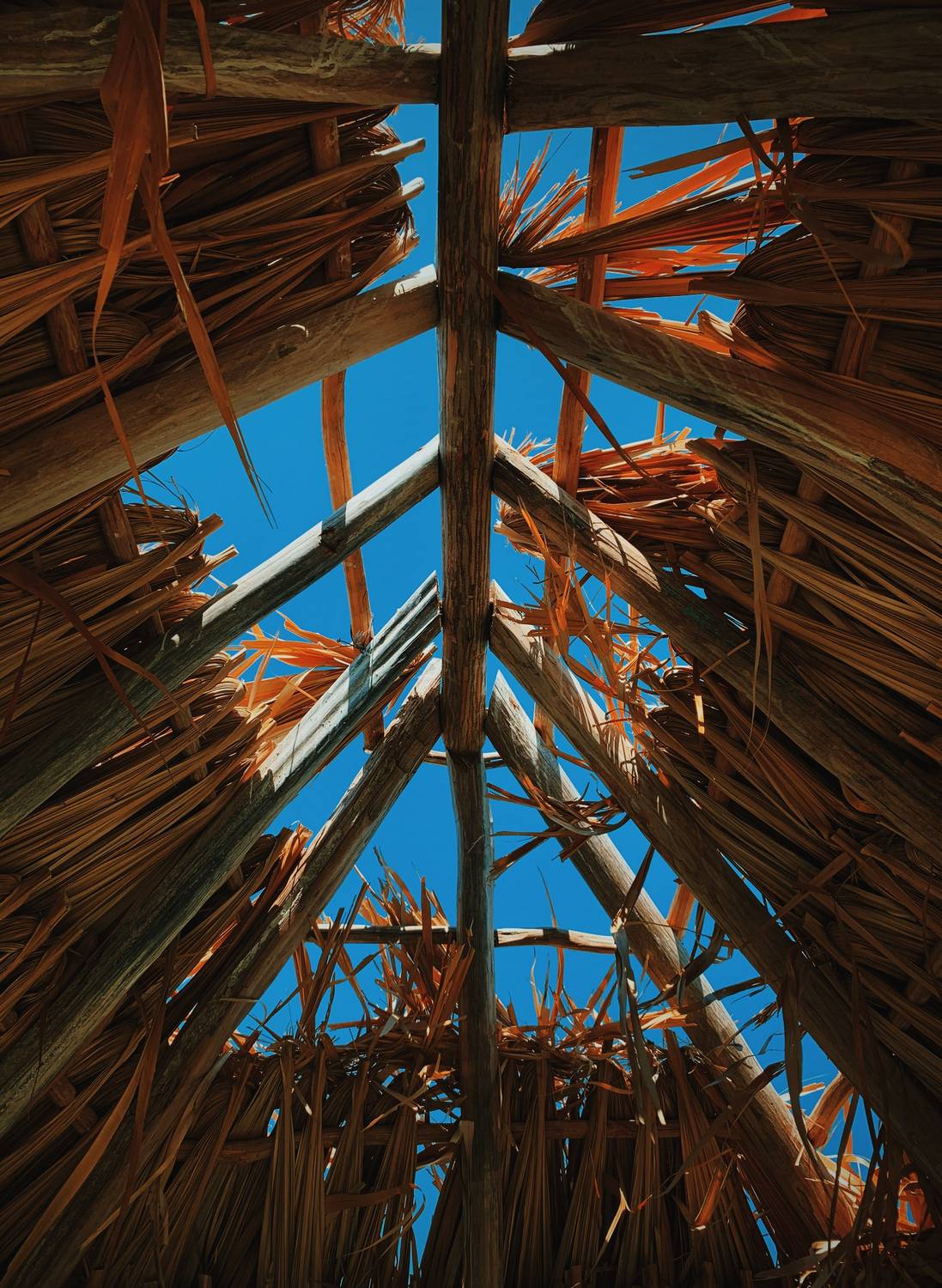

How to dry construction timber? Wood drying becomes an important procedure as it increases its durability and deprives it of the possibility of various pests nesting in it. Construction timber is used to build roofs or external walls, so it is worth not to be subject to mechanical damage or cracks. All this is to ensure proper drying of the wood and its proper treatment. So how to dry construction timber so that it serves for years?

Durability and aesthetic appearance

Construction timber, i.e. construction or shuttering timber, is nothing more than wooden boards cut to the appropriate size, properly dried and shaved. Such wood is used to build roofs, walls of houses, gazebos and other wooden structures. It is usually wood obtained from conifers, such as spruce or pine, which are ideal for construction wood. The most frequently chosen wood for frame structures is C24 class wood, which is additionally certified, which confirms the high quality of the sawn timber, its appropriate processing, and also distinguishes it from ordinary wood. The high quality of building materials is the foundation on which the construction of our house will be based, so we must pay all attention to provide ourselves with only the best prefabricated elements.In order for construction timber to be fit for use, it must undergo a drying process, as a result of which it acquires adequate strength, humidity, and resistance to various natural factors. Construction timber is dried by various companies offering the sale of sawn timber, but we can also dry timber that has been cut or purchased in a store.

- http://www.caloriss.pl/fajka-wodna-tyton-haszysz-marihuana/

- https://www.chrzaszcz.com.pl/ile-wazy-kostka-brukowa/

- https://www.lovelove24.com.pl/kiedy-mozna-skorzystac-z-uslug-bezplatnego-ortodonty/

Construction wood drying methods

There are two basic methods of drying wood: natural and chamber drying. Drying in the open air is quite a time-consuming activity. We must be careful that the wood is not exposed to too much sun, and we must protect it from rain. Such wood loses its moisture during dry and warm days, but it dries from two to seven months, which makes the process long-lasting. To shorten this waiting time, wood can be placed in special chambers that work in two ways. They use an air flow mechanism and heat up the temperature, which means that hot air flows around the wood and dries it evenly on all sides. This allows you to control the entire drying process, achieve the appropriate humidity, and shorten the process to a week or several weeks.

Drying wood in natural conditions

Although we must be careful that the wood does not get wet, it is said that the wood dries even when wet. Of course, drying significantly accelerates this process, but the point is not to deprive the wood of all moisture, but to reduce it to the appropriate values. When drying wood in a natural way, we place it in the open, stacked on top of each other in so-called stacks. How to dry construction timber?We can collect them in the open air, but it is recommended to use specially adapted halls for this process.

Drying under the roof makes it much easier for us to protect the wood against changing weather conditions, which means that drying can also take place all year round. It is important to provide the wood with fresh air and to protect it from rain and sun, which can prevent it from deforming. Wood dried by natural means can be additionally dried in drying chambers, giving it its final form and reducing its moisture content. These types of dryers work with areodynamic methods, heating the air inside the chamber.

Unnatural methods of drying wood

Thanks to drying in appropriate chambers, we can do this work without being dependent on weather conditions. Cold, frost or rain can significantly extend this process, but also contribute to lowering the value of our wood for frame structures. Natural drying thus becomes an activity dependent on external conditions. Modern technology allows us to use more advanced methods of drying construction timber. Chamber drying of wood, e.g. class C24, takes place in special drying rooms at high temperature. Additionally, chamber drying helps to eliminate all pests and fungi attacking the wood. This type of dried wood does not need additional impregnation methods, because it becomes extremely resistant and protected against various weather conditions or even from the return of pests. Chamber drying brings better results than the natural method, e.g. thanks to the possibility of temperature regulation, strictly programmed drying schedule, and adjustable humidity.

Other drying methods

Natural and chamber methods are the most commonly used methods of drying wood for building a frame house, but there are also many other methods that use artificial drying methods. It is possible to dry wood in liquids, with high-frequency currents or in vapors of organic liquids. In this case, construction wood is immersed in liquids with high temperatures, which simultaneously impregnate it, is exposed to an electric field that evenly heats the wood particles, or, using vapors of various chemical compounds, the wood is dried. These methods, however, are sometimes very costly and also risky, because, for example, various chemical compounds used, release many toxins. Electric drying, can greatly increase our electric charge,and drying with chemicals can be hazardous due to explosion. Anyway, these methods are also highly effective and sometimes used in industry to dry construction timber, which in the same way becomes durable and resistant, and also acquires the appropriate quality.

The drying of construction timber is the most important part of obtaining the raw material for building a house. This type of prepared lumber becomes a durable and resistant material, so we must be careful to treat the wood properly throughout the drying process. As a result, we get a product that no longer needs additional protection in the form of impregnation, because it is durable enough, but we can impregnate those parts that will be outside, and this will additionally protect them from weather conditions. In fact, depending on the time we can devote, the natural method is undoubtedly longer, but less expensive, while other methods, i.e. the chamber method, will require additional machines and money.Therefore, the appropriate help of a specialist who knows the methods of drying construction timber in practice may become essential in the entire process.

Zobacz także

-

How to decorate the interior - a review of wall wallpapers

-

Car workshop - how to choose the perfect one?

Car workshop - how to choose the perfect one? It is fair to say that…

-

How to find a good dentist and how to get to know him?

How to find a good dentist and how to get to know him? Nowadays, a…

-

How to choose a gaming laptop?

How to choose a gaming laptop? The processor in a gaming laptop is even more…

-

The history of the bongo

The history of the bongo. Popular bongs are nothing more than a type of hookah…

Kategorie

Artykuły

- When should you consider visiting an orthopedist?

- How much money do you need to open a pawnshop?

- How to find a good dentist and how to get to know him?

- Employees from Ukraine

- Selling a house, or what is worth remembering and what increases the attractiveness of the property?

- Horse riding – what should you know about it?

- Insurance glossary – a compendium in a nutshell

- What is the carrier’s OCP?

- Is it worth renting a tow truck?

- Positioning of websites, i.E. What to do to climb the search engine ranking ladder

- Is chiptuning safe?

- How to decorate the interior – a review of wall wallpapers

- Gift jewelry

- Properties for sale – what is worth remembering and what encourages customers to buy?

- Sardinia – heaven on earth

- The history of the bongo

- Own funds and the purchase of an apartment

- A stylish and unusual place for your socket

- Some tips on how to design a good banner ad

- Dental implants – find out more!

- Car rental – customer and business

- Femininity in material, i.e. Underwear

- Pages in wordpress – design

- How to choose a good accounting software

- How to choose legal services

- Interactive equipment in schools

- Programming robots as a christmas present

- Fashionable interior design

- Advantages of a touchless car wash

- Why choose an accounting service

- Good light = healthy eyes. Which lamps to choose for an apartment?

- What is the work of a surveyor?

- At a beautician over sixty: what treatments to choose?

- Are you buying a new apartment? Check the developer first

- How many degrees should you wash children’s clothes?

- How to choose a gaming laptop?

- Tempered glass and a protective film – what to choose?

- Which exterior door to choose

- Products for young children – how to choose good cosmetics?

- Renting apartments in the capital, and efficient investment management

- Photovoltaics will change our planet

- Who is a podiatrist?

- Coffee shops – how to recognize a good coffee shop

- Emporio Armani – premium fashion that conquers the world

- Private investigator – what services does he offer

- Changing the silhouette using the small steps method

- Organize the perfect conference

- Thermoactive clothes – for sports and more

- What is car scrapping?

- Why do we need phone calls?

- Accessories useful when moving

- If you graduate from high school, it’s only it!

- Dresses for a wedding and the type of figure

- Types of spa treatments

- Garage doors on private properties. How to choose and match the garage door?

- Retirement home – what should you consider when choosing it?

- Recuperation and heat pumps – application

- What should you know before the hair transplant procedure?

- Redecoration of the apartment

- Characteristics of wooden structures